In India, the local government has decided to allocate $15.2 billion in government funding for the construction of chip manufacturing plants.

Part of the mentioned investments will be directed to the implementation of the Tata Group project. In this case, it means the construction of the first large chip manufacturing plant in India. The decision to approve the investment of the industrial initiative proposed by Tata Group was made by the cabinet of the current Prime Minister of the South Asian country, Narendra Modi.

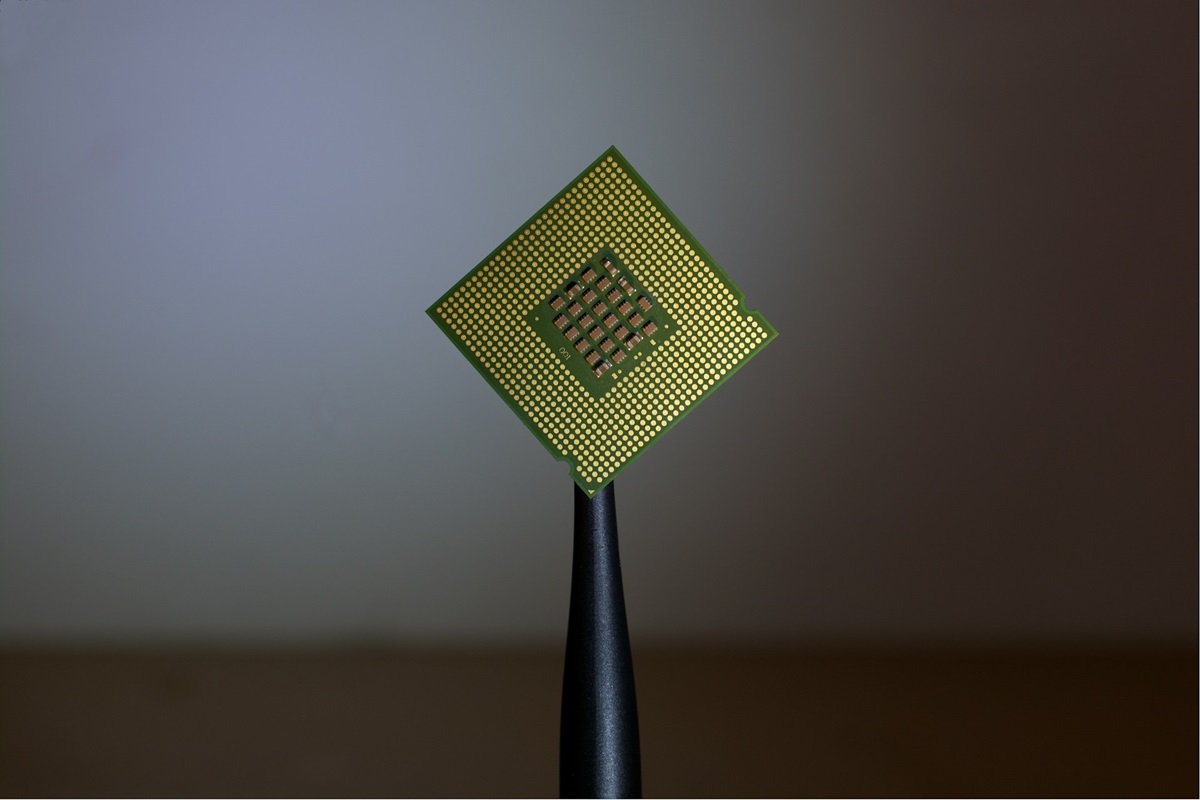

The cost of the specified project is $11 billion. The plant, which has yet to be built, will fabricate about 50,000 wafers monthly. The Minister of Technology Ashwini Vaishnaw announced this during a conversation with journalists in New Delhi on Thursday, February 29.

The Government of India has also approved the allocation of government funding for the implementation of another Tata Group project involving the construction of a microcircuits assembly plant. The cost of this industrial initiative is $3 billion.

Another part of the government funding will be allocated for the creation of a joint packaging venture between the Japanese Renesas Electronics Corp. and CG Power and Industrial Solutions Ltd, part of the ownership structure of the Murugappa Group.

So far, all projects are ideas, the materialization of which is the near future task. At the same time, these plants will embody India’s ambitions in the sphere of semiconductors.

The Narendra Modi administration is committed to implementing measures to develop domestic chip-making production facilities. Currently, India is striving to become one of the world’s main suppliers of microcircuits, which are necessary for the operation of complex systems of advanced technologies, among which the most significant are artificial intelligence models and self-driving cars.

Nowadays, many countries around the world are seeking the development of AI and the creation of homegrown production facilities for making chips. The successful implementation of appropriate efforts can ensure the technological sovereignty of the state. Industrial self-sufficiency is a strategic interest. Supply chain disruptions during the coronavirus pandemic are a confirmation of this thesis.

Ashwini Vaishnaw said that construction of one of the chip manufacturing plants will begin within the next 100 days. In this case, it means the implementation of the project proposed by the Tata Group.

Currently, New Delhi is also striving to gain foreign companies specializing in the production of chips. As part of the relevant intentions, India plans to use the incentive experience that prompted Apple Inc. and its partners to make and sell iPhones in this country. If New Delhi’s efforts are effective, a giant manufacturing sector will be created.

It is worth noting that the current historical moment in the context of the state of affairs in the sphere of geopolitical relationships is a good one for the realization of India’s intentions. Against the background of the deteriorating state of interaction between Beijing and Washington, many companies are seeking to diversify production outside China, but at the same time need to maintain a manufacturing presence in Asia. Against the background of these realities and related tendencies, India can become an alternative industrial center.

The semiconductor fund has already helped American memory chip manufacturer Micron Technology Inc. to establish a $2.75 billion assembly plant in the western Indian state of Gujarat.

Tata Group is expected to partner with Taiwan’s Powerchip Semiconductor Manufacturing Corp., although negotiations have also been held with United Microelectronics Corp. The plant, which will be built as part of the mentioned collaboration, is designed for making chips using 40-nanometer or older technology. Similar microcircuits are applied in airplanes, automobiles, consumer electronics, and defense systems.

Tata Group, which has a value of $150 billion, also announced its intention to begin construction of a chip manufacturing plant in the city of Dholera, located in Gujarat, in 2024. The production capacity of this factory is 50,000 wafers per month. This is a very moderate indicator compared to the capabilities of plants of similar industrial purpose in other countries of the world.

Tata Group is committed to investing billions of dollars in high-tech businesses. The company currently operates India’s largest smartphone component manufacturing plant. More than $700 million was spent on the construction of this factory. Also last year, the company acquired a local Apple supplier, which is Wistron Corp. Moreover, Tata Group plans to build its iPhone manufacturing plant.

The semiconductor industry is gradually transforming into a space of geopolitical competition. Access to advanced technologies largely determines a country’s potential, including in the context of economic prospects and from the point of view of defense potential. The level of dependence of the capabilities of states on technological capacities will increase since the era of global digitalization has already begun in the world. The United States, Japan, and China are investing heavily in the development of domestic advanced manufacturing.

As we have reported earlier, Google Reportedly to Start Manufacturing Pixel Smartphones in India by Next Quarter.