Taiwan Semiconductor Manufacturing Co. (TSMC) has announced another delay in commissioning its plant in the US state of Arizona.

This problem is an obstacle to the realization of the intention of the administration of the current United States President Joe Biden to increase the volume of domestic production of critical components. The cost of the Taiwanese manufacturer’s plant, located in Arizona and standby mode for later commissioning, is $40 million.

It should be clarified that the mentioned factory is currently under construction. Initially, the Taiwanese manufacturer planned to put this production site into operation in 2026. Over time, the company announced that the plant’s functioning would begin in 2027 or a year later.

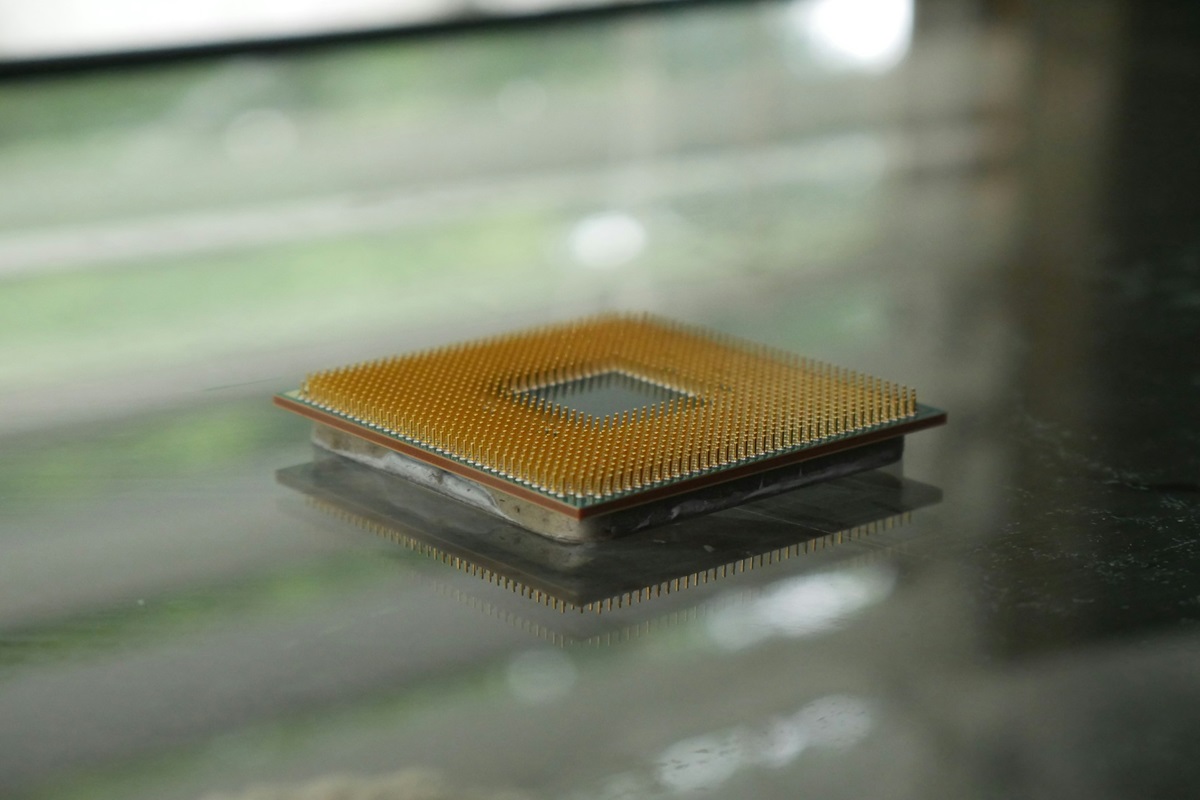

The manufacturing site in Arizona is TSMC’s american second factory. Last summer, the company announced that the launch of its first plant in the United States would take place in 2025. Initially, this factory was supposed to be put into operation by the end of 2024. The specified plant, which is also located in Arizona, will produce 4-nanometer chips. The company cited a shortage of skilled labor and costs that turned out to be higher than expected as the reasons for the factory’s later commissioning.

Chairman of the Management Board Mark Liu said during the TSMC revenue conference in Taipei on Thursday, January 18, that the company’s foreign solutions are based on customer needs and the required level of government subsidies or other support.

At the second plant in Arizona, which will be put into operation in 2027 or 2028, the Taiwanese manufacturer will launch making 3-nanometer chips. It is expected that this factory will be more advanced than the first production site, which is expected to start operating in 2025. At the same time, the company said Thursday that incentives from the US government will help determine how advanced the technology will be. This statement creates a kind of uncertainty about what TSMC’s second American plant will be in terms of production capabilities.

Wendell Huang, the company’s chief financial officer, said that after the setbacks associated with the first factory in the United States, it was decided to delay the construction of a second production site in this country. TSMC is currently in talks with the US government about incentives and tax credits. Wendell Huang, in the context of the difficulties associated with launching production in the United States, noted the problem of hiring staff in Arizona and stated that the company is in constant communication with the local labor union.

Postponing the commissioning of TSMC’s American plants is a problem not only because of the slow pace of implementation of the plan. In this case, an important aspect of the current situation is that during the so-called delayed start period, the process of developing semiconductor technologies can reach new heights. Against the background of potential advances of an advanced nature, 3-nanometer chips may turn out to be an outdated development.

Joe Biden signed the Chips and Science Act in August 2022. As part of this initiative, the US government intends to provide subsidies worth tens of billions of dollars to chip manufacturers operating in the United States. At the same time, the administration of the American president has not yet allocated grants to large makers of microcircuits, such as TSMC or Intel. So far, government support has been provided to companies whose activities do not have a significant impact in the context of the overall scale of the semiconductor industry.

TSMC also has plans to build a factory in Japan. The company has already received financing from Tokyo. It is expected that the launch of production in Japan will take place at the end of the current year.

As we have reported earlier, TSMC Revenue Exceeds Forecasts.